- Toronto +1 (416) 633-5921

- Burlington +1 (905) 581-4015

- Ottawa +1 (613) 731-6224

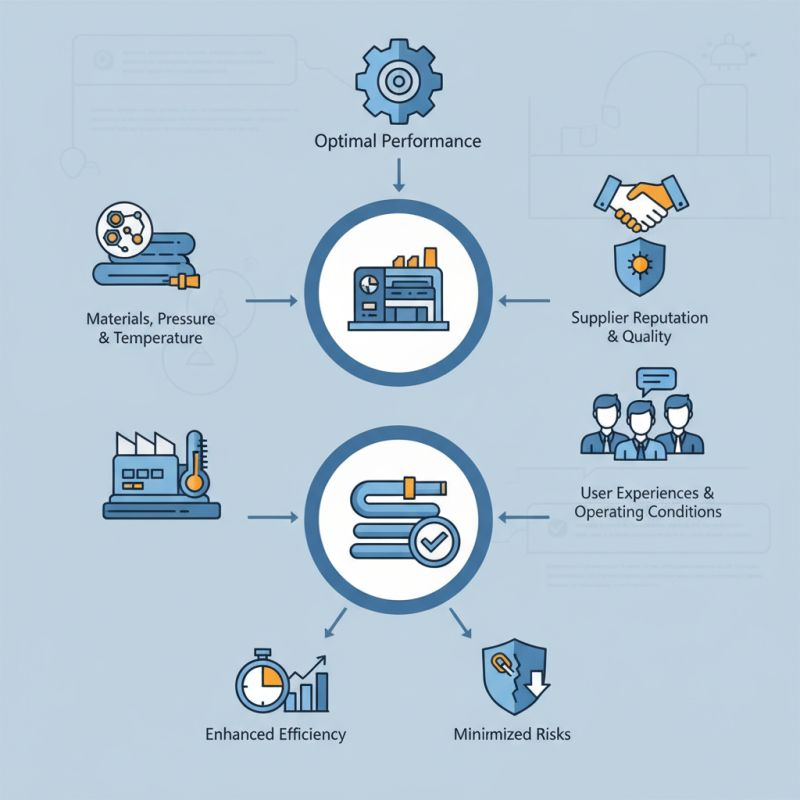

Choosing the right hydraulic hose for sale is crucial for ensuring optimal performance in various applications. The global hydraulic hose market is projected to reach $3.64 billion by 2026, indicating a significant demand. Companies rely on durable hoses to prevent leaks and failures in hydraulic systems. With diverse options available, selecting the best hydraulic hose can be overwhelming.

Quality matters. A poor choice may lead to costly downtime and repairs. According to industry reports, nearly 30% of hydraulic failures are attributed to inadequate hose selection. The materials, pressure ratings, and temperature limits all play vital roles. It’s essential to assess the specific needs of your machinery before making a purchase.

While searching for hydraulic hose for sale, consider the reputation of the supplier. A well-reviewed supplier often indicates higher quality products. Don’t overlook user experiences. Many users emphasize the significance of matching hoses to their operating conditions to avoid issues down the line. Ultimately, the right hose not only enhances efficiency but also minimizes risks associated with hydraulic operations.

Hydraulic hoses are crucial components in various industries. They transfer hydraulic fluids efficiently. Understanding the types of hoses is essential for proper application. There are multiple types, including rubber, thermoplastic, and metal hoses. Each type has its strengths and weaknesses. Rubber hoses are flexible, but they may not withstand extreme temperatures. Thermoplastic hoses often resist abrasion, yet they can be less durable over time.

Applications vary widely. Construction, agriculture, and manufacturing all rely on hydraulic hoses. A report by the Fluid Power Society states that hydraulic systems in construction can improve productivity by 25%. However, choosing the wrong hose can lead to failures. For instance, using a hose not rated for a specific pressure can cause leaks. Data shows that over 50% of hydraulic system failures stem from improper hose selection.

Issues can arise with compatibility, too. Hoses must be compatible with the fluids they transport. Misalignment can create leaks, leading to costly repairs. Industry studies have shown that preventative maintenance can reduce these failures by 30%. Consider these factors when selecting hydraulic hoses. It can save time and future headaches.

Selecting the right hydraulic hose is crucial for optimal performance. There are key factors to consider. First, assess the pressure rating. Each application has a specific pressure requirement. Ignoring this can lead to hose failure. Always choose a hose that can handle your system's maximum pressure.

Next, think about the hose's material. Different applications require different materials. For example, rubber hoses are flexible but may not withstand harsh chemicals. On the other hand, steel-reinforced hoses can endure extreme pressures but might be less flexible. Analyze your operational environment carefully.

Lastly, consider the hose size. A hose that is too large can cause pressure loss. If it’s too small, it can burst under pressure. Measure your fittings accurately. Small mistakes in measurement can lead to inefficiencies. Reflect on these factors to ensure a suitable choice for your hydraulic needs.

When selecting a hydraulic hose, material choice significantly impacts performance. Rubber and thermoplastic are common options. Rubber hoses are flexible and durable, suitable for high-pressure environments. They can withstand temperatures up to 100°C, making them ideal for various applications. However, they may be less resistant to weathering and chemicals.

On the other hand, thermoplastic hoses can handle a wider range of fluid types. They are lighter and often more resistant to abrasion. Data from industry reports suggest that thermoplastic hoses can show a lifespan improvement of up to 40% compared to rubber counterparts under specific conditions. However, costs can vary, and users need to evaluate their specific needs.

Sealing and compatibility are essential too. The hose must be compatible with the hydraulic fluids it will carry. Using mismatched materials can lead to premature failures. For example, certain oil-based fluids can degrade rubber, while thermoplastics may not perform as well under extreme pressures. Reflect on the application environment and the nature of fluids involved to ensure optimal performance.

Choosing the right hydraulic hose requires careful consideration of size and pressure ratings. The size of the hose is not just about fitting it into connectors. It affects flow rate and efficiency. A hose that's too small can restrict flow, leading to overheating. On the other hand, an oversized hose may introduce unnecessary weight and cost.

Pressure rating is equally crucial. Every hydraulic system operates under specific pressure conditions. If the hose cannot withstand these pressures, leaks or bursts can occur. Understand the maximum operating pressure in your application. It is wise to choose a hose that exceeds these limits for safety.

Keep in mind, sometimes mistakes happen. You might purchase a hose that seems adequate, only to find that it doesn’t fit or perform as expected. Measuring your system's needs accurately is essential. Always double-check specifications. If you're unsure, consult with a professional to avoid costly errors. Understanding these factors will lead you to better choices in hydraulic hoses.

| Hose Size (ID) | Pressure Rating (PSI) | Material Type | Application |

|---|---|---|---|

| 1/4 inch | 3000 PSI | Nitrile Rubber | Agricultural Equipment |

| 3/8 inch | 4000 PSI | Polyester Reinforced | Construction Machinery |

| 1/2 inch | 3000 PSI | Thermoplastic | Hydraulic Lifts |

| 3/4 inch | 2500 PSI | Rubber with Steel Reinforcement | Industrial Equipment |

| 1 inch | 2000 PSI | Braided Steel | Marine Applications |

Proper maintenance of hydraulic hoses is crucial for their longevity. Regularly check for wear and tear. Look for cracks, blisters, or abrasions in the outer layer. Any sign of damage should be addressed immediately. Ignoring these issues can lead to sudden hose failure.

Another key aspect of maintenance is cleanliness. Keep your hoses free from dirt and contaminants. Dirt can enter the hydraulic system and cause severe damage. Clean the hose fittings regularly to maintain a tight seal.

Also, ensure proper routing of hoses. Avoid sharp bends or kinks that could weaken them.

Finally, consider storage conditions. Hoses should be kept in a dry and cool environment. Avoid exposure to harsh chemicals or extreme temperatures. Improper storage can degrade hose materials over time. Reflection on your current maintenance practices could reveal areas for improvement. Maintaining hydraulic hoses requires consistent effort and awareness.

Call us one of our 3 offices across Ontario, Canada

Thanks for contacting us!

We'll get back to you as soon as possible.