- Toronto +1 (416) 633-5921

- Burlington +1 (905) 581-4015

- Ottawa +1 (613) 731-6224

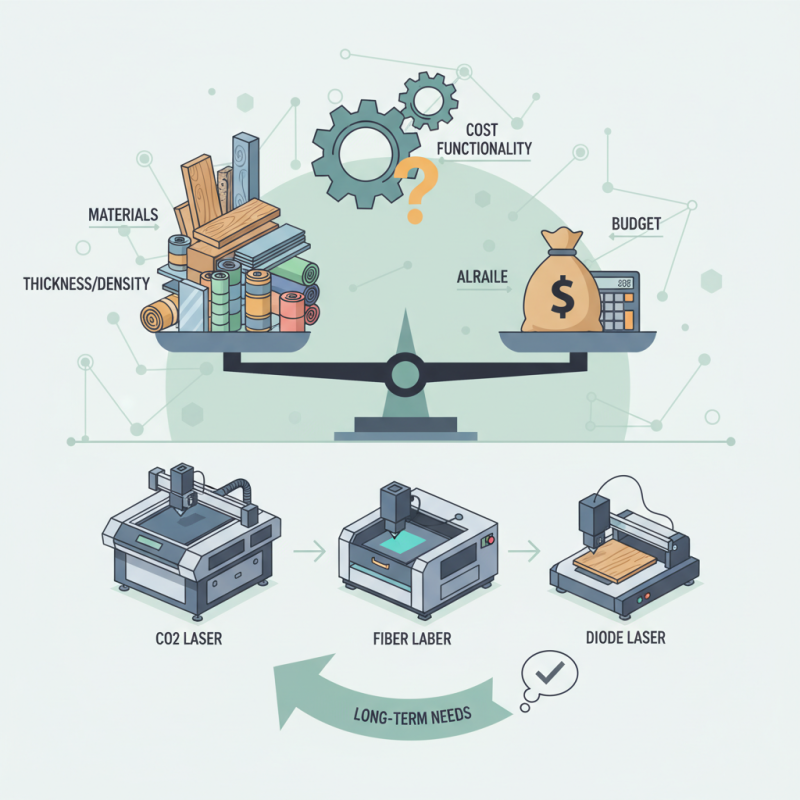

Choosing the right laser cutting machine can be daunting. The market is filled with various options tailored to different needs. Each machine boasts unique features designed for specific tasks. This diversity means the decision should not be taken lightly.

Consider the materials you plan to cut. Different machines perform differently based on material type. Factors like thickness and density play a significant role in the selection process. Think carefully about these aspects.

Additionally, don’t overlook your budget. High-quality machines can be costly, but cheaper options might compromise performance. Reflect on your long-term needs. Investing wisely can save you headaches later. Balancing cost and functionality is crucial in making the right choice.

When choosing a laser cutting machine, understanding your material and thickness needs is crucial. Different materials react differently to laser cutting. For instance, metals require higher power settings, while wood and acrylic can be cut with lower power. According to industry reports, metal cutting can need up to 500 watts for thicker sheets, while thinner wood may only require around 40 watts. It's essential to gauge the material's properties before making a decision.

Thickness is another key factor. The maximum thickness for effective cutting often depends on the machine's wattage. Machines operating at 300 watts can typically cut through materials up to 6 mm thick, while those at 1000 watts may cut through materials up to 20 mm. Consider your projects' requirements carefully, as a thicker material may demand a more powerful machine.

Tips: Always check the manufacturer's specifications for maximum thickness limits. Test your chosen material to ensure the machine settings yield clean cuts. The room for error is small—any miscalculations can lead to burned edges or incomplete cuts. Troubleshooting cuts may take time and effort. Take this step seriously to improve your craft.

| Material Type | Max Thickness (mm) | Laser Power (W) | Cutting Speed (mm/s) | Recommended Machine Type |

|---|---|---|---|---|

| Acrylic | 20 | 60 | 300 | CO2 Laser |

| MDF | 15 | 80 | 200 | CO2 Laser |

| Stainless Steel | 10 | 100 | 80 | Fiber Laser |

| Aluminum | 8 | 150 | 90 | Fiber Laser |

| Wood | 25 | 60 | 400 | CO2 Laser |

When selecting a laser cutting machine, understanding the differences between CO2 and fiber lasers is crucial. CO2 lasers are versatile and can cut various materials. They work well on wood, acrylic, and textiles. However, they may struggle with metals, especially thicker pieces. This limitation can lead to frustration during projects requiring metal cutting.

On the other hand, fiber lasers excel at cutting metals. They produce a focused beam that penetrates surfaces easily. If your projects involve steel, aluminum, or copper, fiber lasers could be a better choice. Yet, they might not perform as well on non-metal materials. Balancing these options is essential. You need to consider the materials you work with most.

Another point to ponder is cost. CO2 machines can be less expensive initially, but you may encounter hidden costs. Maintenance and replacement parts may add up over time. Meanwhile, fiber lasers tend to have a higher upfront cost but lower maintenance needs. Understanding these trade-offs can help you make a more informed decision for your specific needs.

When choosing a laser cutting machine, power and speed are crucial. Power determines the material it can cut. Higher wattage machines can handle thicker materials. For example, a 100-watt laser cuts through metal more efficiently than a 30-watt one. However, using excessive power can lead to unwanted heat-affected zones. This can weaken the cut edges, making them less durable. It's imperative to balance power with the type of material you work with.

Speed is another vital factor. Faster cutting saves time but may reduce precision. Slower speeds allow for cleaner edges. Consider the complexity of your projects. Intricate designs demand attention. A machine that is too fast could compromise the detail. Note that speed settings sometimes require adjustments based on material type. Reflecting on your needs is essential. What are your priorities? Is it speed, or is it quality? Finding the right mix won't always be easy. But it's a key step towards successful projects.

Choosing the right laser cutting machine can be a daunting task. Key features like software, cooling systems, and maintenance play a crucial role in your decision-making process. A user-friendly software interface helps you manage designs efficiently. Look for options that support common file formats. This makes your workflow smoother. A complex software can slow you down. Not ideal for tight deadlines.

Cooling systems are vital to maintaining optimal performance. Efficient cooling prevents overheating. It prolongs the lifespan of the machine. Air-cooled systems are easier to maintain. Water-cooled systems offer better performance but require more upkeep. Consider the environment where the machine will be used. Dusty or hot spaces may require additional cooling solutions.

Maintenance can be easily overlooked. Regular maintenance ensures longevity and reliability. Simple cleaning routines are often neglected. You don’t want to deal with performance issues later. Assess the availability of replacement parts as well. It’s wise to have easy access to any necessary components. Regular checks on the machine save you from potential headaches down the line.

Budgeting for a laser cutting machine involves careful calculation. The initial purchase price is only one of many costs. You also need to consider operational expenses. These include materials, maintenance, and energy consumption. It's easy to underestimate these factors when budgeting.

Return on investment (ROI) can be tricky to assess. You might think that a more expensive machine guarantees better results. However, this isn't always true. Some machines may require more care or inefficiently use materials, affecting profitability. Take time to evaluate your unique needs. Research different features and how they impact efficiency. It's vital to align machine capabilities with your business goals.

While it's tempting to go for the lowest price, think long-term. Sometimes cheaper machines can lead to higher costs down the line. This happens when they break down often or cannot handle the volume you need. Make sure to factor in potential upgrades as your business grows. A thoughtful budget will help you achieve better outcomes in laser cutting projects.

Call us one of our 3 offices across Ontario, Canada

Thanks for contacting us!

We'll get back to you as soon as possible.